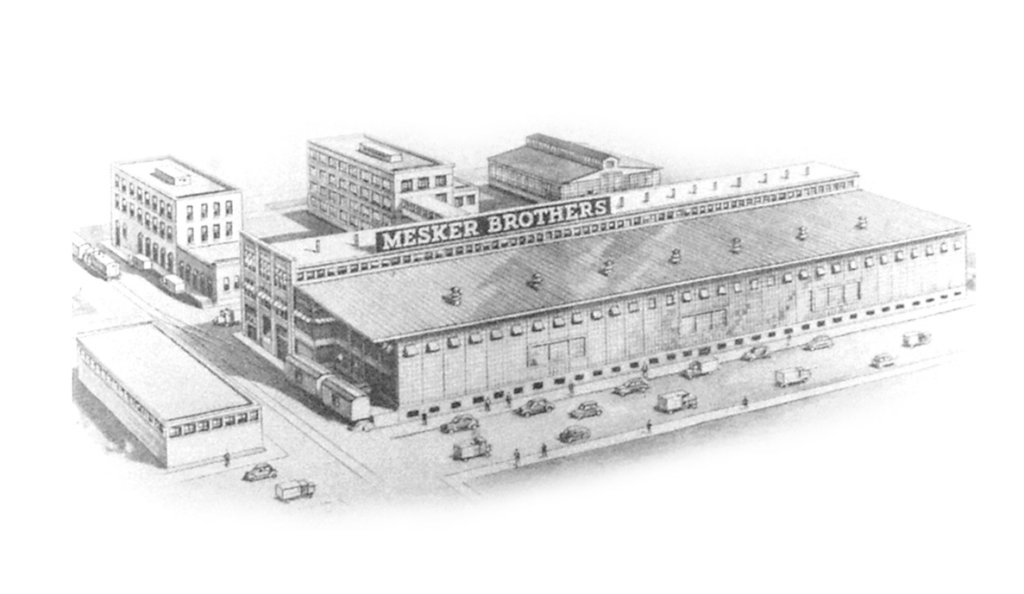

WHO ARE WE?

It’s true. We invented the metal door

If superior quality and a great value are primary concerns, then consider investing in our line of stock hollow metal doors and frames. After all, we invented the metal door over 150 years ago.

Mesker’s no-compromise values, backed by a nationwide group of distributors and exceptional customer service, have made us a distinguished national leader among architects and contractors. We engineer our

doors and frames to be the most rugged and durable in the commercial construction industry, with best-in-class fit & finish. We frequently exceed Steel Door Institute and Architectural Design specifications.

Our mantra is simple. We cut metal, not corners.

We bend steel, not rules. And we shine as the oldest hollow metal door and frame fabricator in America

A quality door right down to the core

Quality comprises many things, i.e. listening to our customers’ needs, utilizing superior engineering know-how, using only premium components, and guaranteeing complete customer satisfaction. That’s why we introduced the non-handed “one door four cores does it all.” Our door is easier to install because it eliminates handing issues at the job site. In addition, it simplifies inventory and makes our system more economical for our customers.

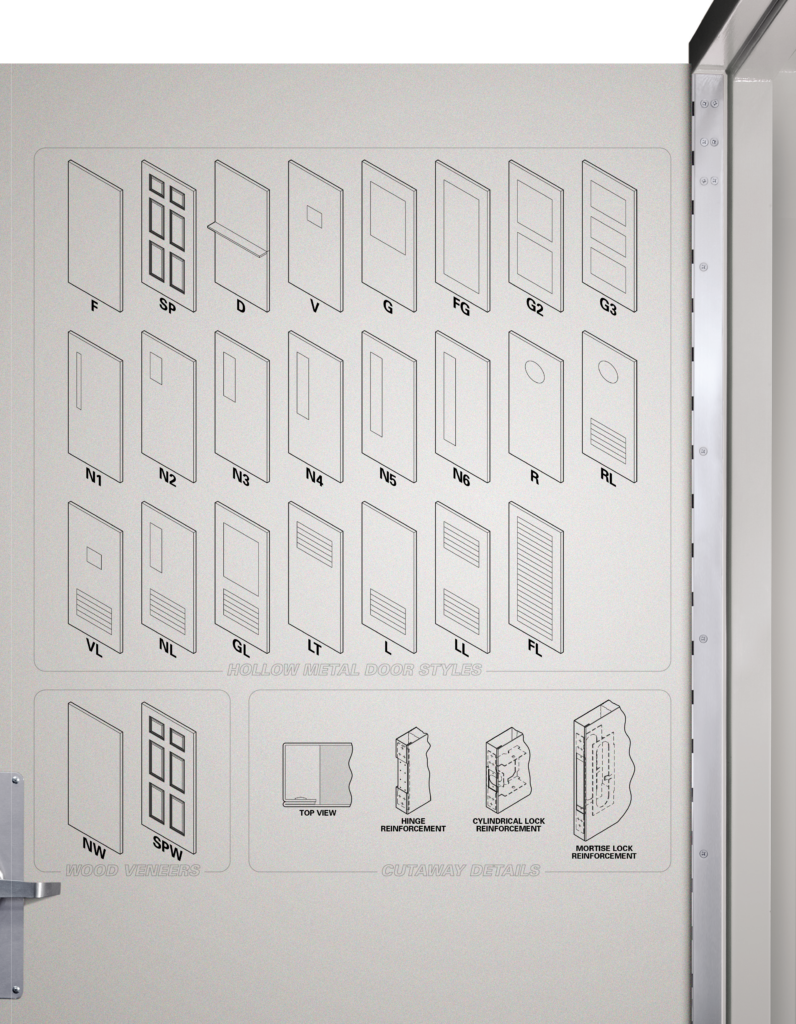

Mesker boasts one of the largest lines of door products from a single hollow metal manufacturer. We offer an array of door styles to complement your building design using our standard, yet versatile N-Series unit. Choose from our custom-size light kit and louver doors, or select from the more decorative multi-panel doors. We also have a large variety of custom doors including sound doors and bullet-resistant doors.

All Mesker units comply with SDI,[1] ANSI, ASTM and ADA requirements and exceed all test criteria available for physical endurance and cycle of use. To ensure superior fit and finish, in addition to maximum unit life, every Mesker door is manufactured as specified:

[1] SDI 100 Level 1 and 2 government design specifications [2] Per UBC-72(97), UL10B, and UL10C specifications

[3] Govt. 161 per ANSI A115.2 lock front

[4] Govt. 86 per ANSI A115.1 lock front

Specifications:

- Our standard 18 gauge door is built for commercial-duty while our 14 gauge is designed for abusive applications. Select from 20, 18, 16 or 14 gauge, cold-rolled steel. For corrosive applications, we recommend A60 Galvannealed steel.

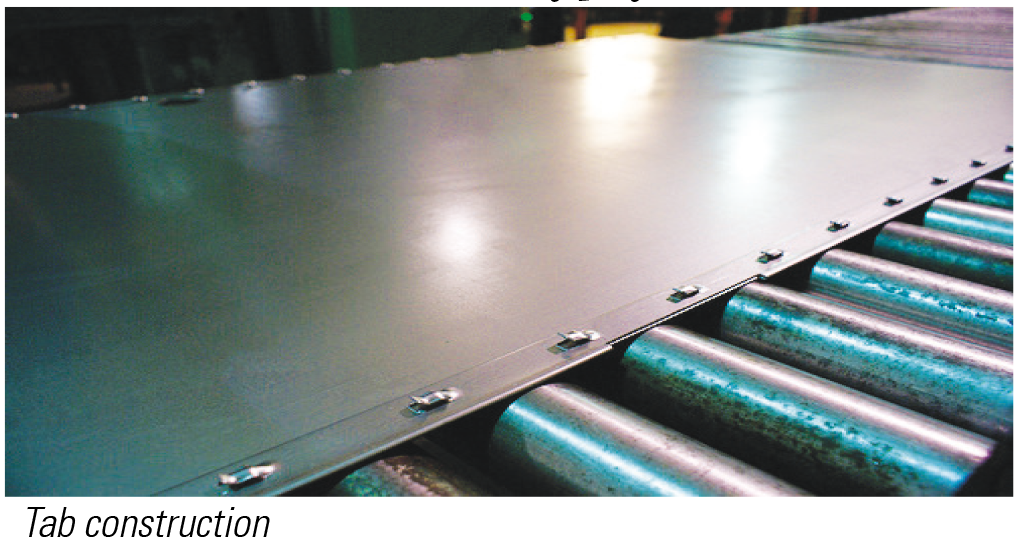

• We use an exclusive, interlocking pan and lid design fortified using plug-welds to prevent sagging and increase door stiffness by 40%.

• We use 3/16-inch, 7 gauge hinge reinforcements. The top hinge reinforcement is an extra-long, high frequency reinforcement with 50% more welds and extra length for added strength.

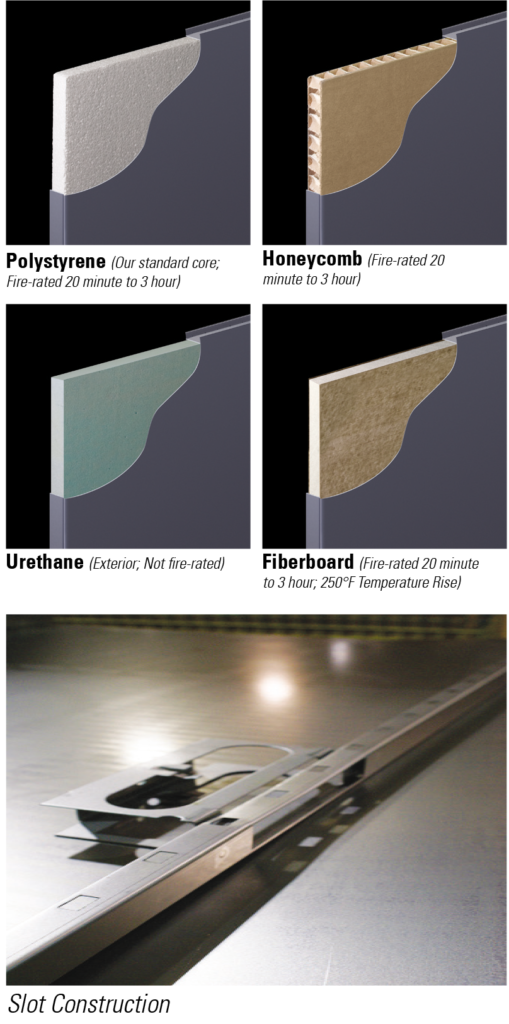

• Choose from polystyrene, honeycomb, urethane, or fiberboard cores.

• We use hemmed edges for 20-16 gauge units which provides an extra smooth transition between faces. For a classier look and stronger door, try our new patent-pending eNViouS (NVS) seamless door as an upgrade.

• We use NVS seamless edges standard for 14 gauge doors.

• All doors are universal handed, which can be attributed

to our mirrored hole pattern and reversible filler plate.

• All doors come with a closer reinforcement box.

• All doors have a lock reinforcement, prepped for a

cylindrical lock with a 2-3/4 backset[3] or a mortise lock

with a 2-3/4 backset.

• We use 16 gauge, recessed top and bottom channels for easy

field trim. Top channel can be made flush at no charge.

• All doors are cleaned, phosphatized, and painted with a single coat of rust inhibitive primer.

• Now available in thousands of prefinished colors